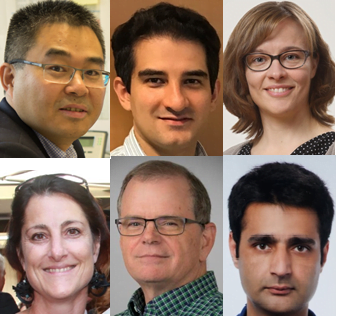

De-Yi Wang, IMDEA Materials Institute, Madrid, presented different approaches to develop specific nano-materials and architectures as PIN flame retardants in different polymers and the complexity of understanding the mechanisms involved. These include using layered surface materials (LDH) to improve char behaviour by including metal compounds (e.g. iron or nickel) between layers, nano-encapsulation of PIN FRs in MOF (metal organic framework) nano-structures, using nano coatings to improve interface between inorganic flame retardants and polymer matrices.

Gaëlle Fontaine, University of Lille, France, presented studies of thermal degradation of three high performance polymers: PEEK = polyetheretherketone, PI = polyimide and PBO = Poly(p-phenylene-2,6-benzobisoxazole). These polymers are inherently fire resistant, with decomposition temperatures above 600°C and show significant char generation under nitrogen.

Nima Esmaeili, Huntsman, presented tests of zinc and tin stannate as replacements for antimony as synergists for polymeric brominated flame retardants in polyamide 6,6, concluding that zinc stannate offered better performance. Inclusion of zinc stannate (7% loading) and acrylate polymeric brominated flame retardant (15% loading) showed that this limited the reduction in the thermal stability of the polyamide induced by the brominated FR, modified the release of aromatic compounds and generated char formation in fire.

Mark Beach, DuPont, presented a brominated polymer product used for flame retarding polystyrene foams, to replace the brominated flame retardant HBCD which is indicated to be PBT (persistent, bioaccumulative, toxic). The brominated polymer is not B or T. Ongoing tests show that it is stable with no detectable or extremely slow biodegradation, hydrolysis, thermos-oxiditive degradation. Installation and handling instructions should ensure very little exposure to light and tests show that UV degradation impacts only the foam surface.

Teija Tirri, Äbo Akademi University Finland, presented studies of sulphenamides as PIN synergists for phosphorus flame retardants in polystyrene, polypropylene, epoxy and TPU. These sulphur containing, thiyl releasing molecules include aromatic rings (benzothiazoyl, phenyl), giving improved thermal stability. At low loading of 1-3% they show a strong synergy with phosphorus flame retardants, improving fire performance by acting in both the solid and gas phases, and reducing smoke emissions. For example, 2% sulphenamide and 8% spirocyclic phosphate ester achieved UL94-V0 (1.6 mm) in polypropylene. 2.5% sulphenamide alone achieved ISO 11925-2 in polystyrene.

Rashid Nazir, EMPA Switzerland, presented research into synthesis of bridged phosphorus compounds (alkyl sulforne based) and their application as additive flame retardants for polypropylene (PP) and flexible polyurethane (PU). Aromatic bridged compounds were suitable for flame retardation of polyolefin, because of higher thermal stability, and the aliphatic compound was more suitable for application in rigid PU foams.