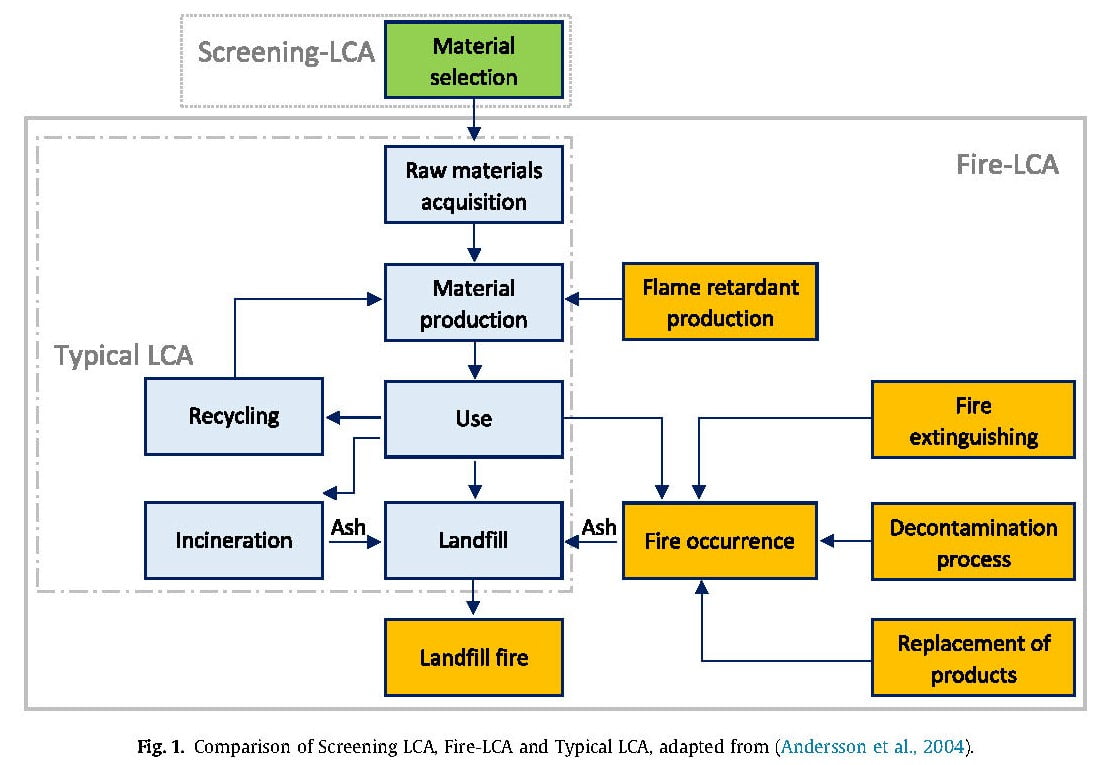

LCAs conclude benefits of PIN FRs but further LCA work is needed to support substitution of halogenated FRs. Samani et al. reviewed FR LCAs, finding only two LCAs specifically comparing flame retardants (Jonkers 2016 – summarised in pinfa Newsletter n° 58, Deng 2016, see below), both of which conclude significant LCA benefits in replacing halogenated by PIN FRs. Several other LCA studies were identified comparing products with / without FRs (Broeren 2016, Dahllöf 2004, Yasin 2018 – these are summarised below). The review concludes that there is a “huge gap” in LCA data on flame retardants, and more generally on plastic additives. They underline that LCAs of PIN flame retardants should be developed to support substitution away from halogenated FRs, considered to pose environmental concerns and progressive regulatory prohibition. LCAs should take into account impact of fires (pollution, materials destroyed).

pinfa’s analysis of the few LCAs identified by Samani et al. (plus one other recent paper) shows that the only two of these provide an LCA comparison between PIN and halogenated FRs: Jonkers 2016 (see pinfa Newsletter n° 58) showed that the largest LCA difference was in the end-of-life phase, with PIN FRs having a preferable LCA; Deng (below) shows preferable LCA for PIN compared to brominated FR.

Ingrao et al. 2020 have published an LCA of nano hydroxyapatite (calcium phosphate) as a PIN flame retardant for leather. They suggest that it would be effective because the hydroxyapatite, which is the same main chemical as bone structure, could bind to collagen present in leather, but no data is included to support this. The hydroxyapatite was lab synthesised by reacting lime with phosphoric acid, resulting in particles c. 100-150 nm length, 5-10 nm thickness. LCA for these raw materials were taken from Ecoinvent. Conclusions are that the main LCA environmental contributions are related to phosphoric acid, but that this depends on the supply chain. No account is taken of possible environmental impacts of fires. The LCA of hydroxyapatite is not compared to other fire safety treatments.

Broeren et al. 2016 compared LCA for a printer panel produced from bio-sourced polymer (PLA) to petro-sourced PP, ABS, PC/ABS, in formulations with or without flame retardants (type of FR not specified). Plastic additive production contributed significantly to LCA, e.g. up to 40% of greenhouse gas emissions. In the only comparable case, PC/ABS with FR (V0) showed higher environmental impacts and higher cost, but was not fire performance classified without FR.

Dahllöf, 2004, produced a report on LCA methodology for textiles, applied to furniture. This compared FR polyester (Trevira CS, phosphorus based) to non-FR cotton and to 85% wool / 15% polyamide PA66. This showed the lowest energy consumption for the Trevira textile (646 MJ for the textile for a 3-seat sofa, 928 MJ for cotton, 1115 MJ for wool/PA). The Trevira also showed lower global warming potential, acidification, eutrophication, water use, chemical use (mainly because of agro-chemicals in growing the cotton and wool) and ecotoxicity and human toxicity both nearly equal lowest, so lowest overall environmental impact.

Yasin et al. 2018, assessed the LCA of an FR cotton curtain (phosphorus FR, not specified, but probably by reference to Yasin 2016: MDPA N-methylol dimethyl phosphonopropionamide plus TMM = trimethylol melamine) comparing two end-of-life scenarios. Results show that end-of-life makes only a minor contribution to LCA, with manufacturing and use phases contributing around half each of e.g. greenhouse impact. The paper does not compare FR with non-FR and only assesses the one type of FR.

Deng et al. 2016, compared LCA of two printed circuit boards: PIN FR (melamine polyphosphate) in a bio-sourced substrate (flax fibres in epoxidized linseed oil), brominated FR (TBBPA) in conventional epoxy resin / glass fibre substrate. Results show considerably lower overall LCA for the bio-sourced + PIN combination, in particular much lower climate change, human toxicity and particulate matter formation impacts. The PIN flame retardant alone shows considerably lower LCA impact than the halogenated FR (fig. 3) and lower climate change and human toxicity (figs. 4 and 5). The authors note the brominated FR’s high terrestrial and marine ecotoxicity.

“Life cycle assessment (LCA) studies on flame retardants: A systematic review”, P. Samani et al., Journal of Cleaner Production 274 (2020) 123259 https://doi.org/10.1016/j.jclepro.2020.123259

“Chemistry behind leather: Life Cycle Assessment of nano-hydroxyapatite preparation on the lab-scale for fireproofing applications”, C. Ingrao et al., J. Cleaner Production, vol. 279, 10 January 2021, 123837 https://doi.org/10.1016/j.jclepro.2020.123837

“Methodological Issues in the LCA Procedure for the Textile Sector. A case study concerning fabric for a sofa”, L. Dahllöf, ESA Sweden, 2004, ISSN 1404-8167 http://cpmdatabase.cpm.chalmers.se/DataReferences/ESA_2004–7.pdf

“Life cycle assessment of flame retardant cotton textiles with optimized end-of-life phase”, S. Yasin et al., J. Cleaner Production 172 (2018) 1080e1088 https://doi.org/10.1016/j.jclepro.2017.10.198

“Life cycle assessment of flax-fibre reinforced epoxidized linseed oil composite with a flame retardant for electronic applications”, Y. Deng et al., J. Cleaner Production 133 (2016) 427e438 http://dx.doi.org/10.1016/j.jclepro.2016.05.172

“Early-stage sustainability assessment to assist with material selection: a case study for biobased printer panels”, M. Broeren et al., J. Cleaner Production 135 (2016) 30e41 http://dx.doi.org/10.1016/j.jclepro.2016.05.159