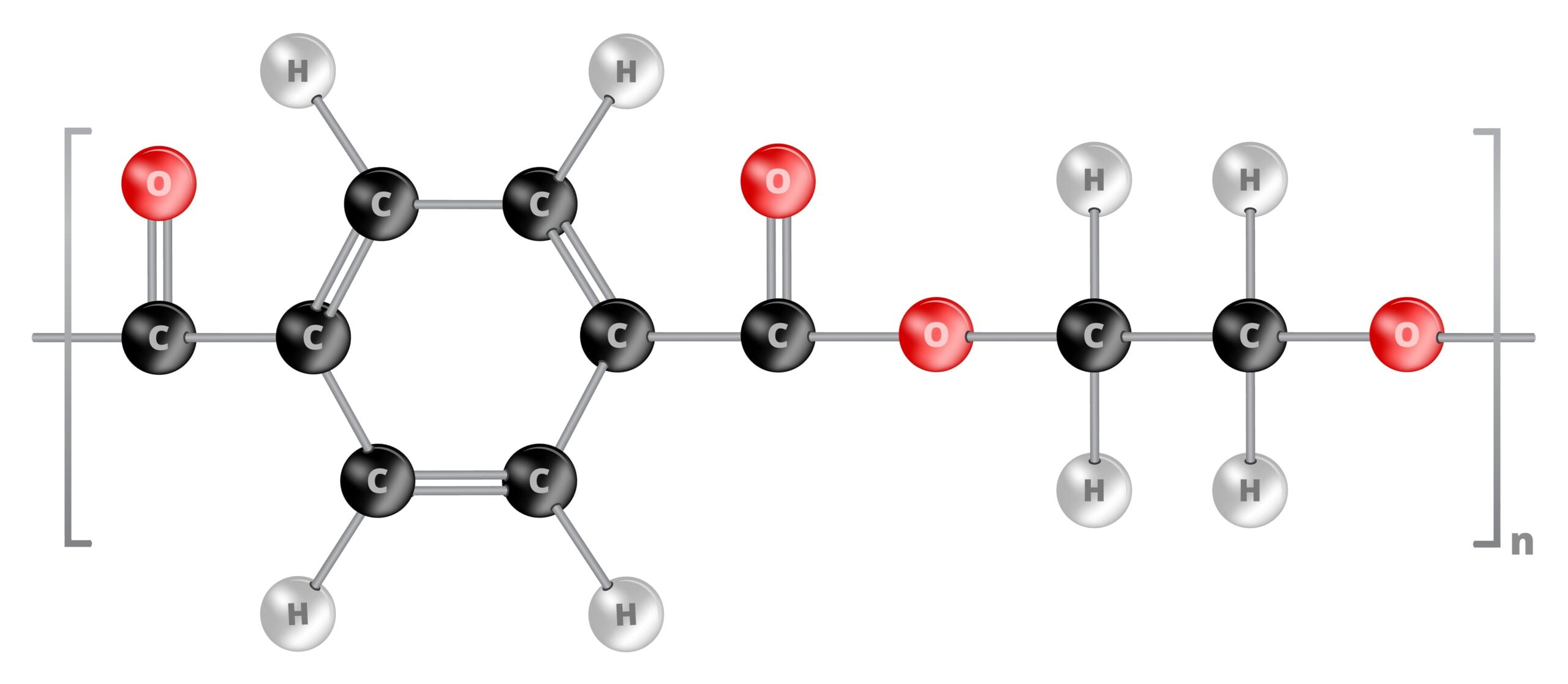

Two phosphorus PIN FRs show to protect polymer properties in recycling (multiple re-extrusion cycles) of PET. Poly(ethylene terephthalate) (PET), a polymer widely used for films and textiles, was tested pure and flame retarded with DOPO-PEPA (5%) or with a phosphate ester (3%). Three re-extrusion cycles were carried out. The DOPO-PEPA containing PET showed less deterioration of material properties than pure PET after mechanical recycling, attributed to DOPO-PEPA improving lubrification and melt properties (stabilisation). The phosphate ester however led to embrittlement of the PET after mechanical recycling, probably by boosting polymer chain branching and extension.

“Investigating thermomechanical recycling of poly(ethylene terephthalate) containing phosphorus flame retardants”, C. Bascucci et al., Polymer Degradation and Stability, vol. 195, January 2022, 109783 https://doi.org/10.1016/j.polymdegradstab.2021.109783

“Enhanced PET processing with organophosphorus additive: Flame retardant products with added-value for recycling”, A. Gooneie et al., Polymer Degradation and Stability 160 (2019) 218e228 https://doi.org/10.1016/j.polymdegradstab.2018.12.028