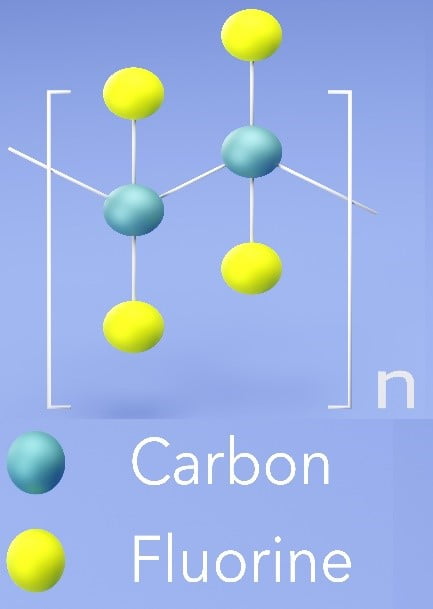

Expert paper, with pinfa-NA, assesses possible non-halogenated solutions to reduce melt-drip fire risk in plastics. Melt-dripping of plastics can propagate fire from burning plastic to other materials. The UL 94 fire performance test therefore requires absence of flaming drips for V0 or V1 rating. The halogenated polymer PTFE (polytetrafluoroethylene, as in Teflon) is widely used at low dosages (e.g. 0.5%), in synergy with flame retardants, to avoid melt-drip in plastics and acts by shearing-inducing fibrillation within the polymer under heat, which increases viscosity. Problems of dispersion of PTFE in plastics are addressed by using e.g. SAN coating (styrene acrylonitrile). However, PTFE is included in the wide class of chemicals “PFAS” (per- and polyfluoroalkyl substances) currently subject to a proposed “Restriction” in the EU. This study discusses a range of PIN compounds which improve the structure of char which can hinder melt-dripping or which increase polymer viscosity (talc, clays, metal hydroxides, zinc borate, silicones, acrylic acid polymers, carbon nanomaterials) as well as other possible solutions such as multilayer coextrusion of different polymers. Some bio-based compounds may also have anti-drip effects, such as lignin, saccharide-based compounds, phytic acid, probably due to char formation. The paper concludes that anti-drip agents are essential for plastic fire safety, that there is rapid development of char-promoters which can somewhat reduce dripping, but that there is today no solution available to replace PTFE in many polymer FR compounds.

“Drip Suppressants in Halogen-free Flame Retardant Systems”, Y. Zhang, G. Whek, R. Avakian, J. Zhou (Case Western University, pinfa-NA). Not yet published. Available to pinfa members. External parties may request a copy from