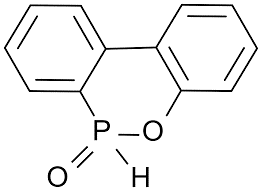

Phosphorus PIN FR DOPO was coated on PA6 textile achieving vertical burn self-extinguishing and wash semi-durable. DOPO cannot be compounded into polyamide because it is not stable at the polymer extrusion temperature. In this study, PA6 fabric (113 g/m2) was coated by dipping in a water – ethanol solution of DOPO (adjusted to pH 4.5) at 80°C for one hour, then curing at 140°C for five minutes, then washing in water. With a phosphorus content of 0.1% – 0.2%, up to 21% reduction in peak heat release rate was achieved and self-extinguishing in vertical burn test. However, with higher DOPO loading, melt-dripping occurred, resulting in failure of the vertical burn test, possibly because DOPO increases melt fluidity. The coated fabric retained vertical burn test performance after 15 wash cycles, probably because of hydrogen bonding between DOPO and PA6, but lost this after 20 cycles.

“Preparation of durable coating for polyamide 6: analysis the role of DOPO on flame retardancy, anti-dripping and combustion behavior”, W-J. Jin et al., Polymer Degradation and Stability, vol. 215, Sept. 2023, 110418 https://doi.org/10.1016/j.polymdegradstab.2023.110418