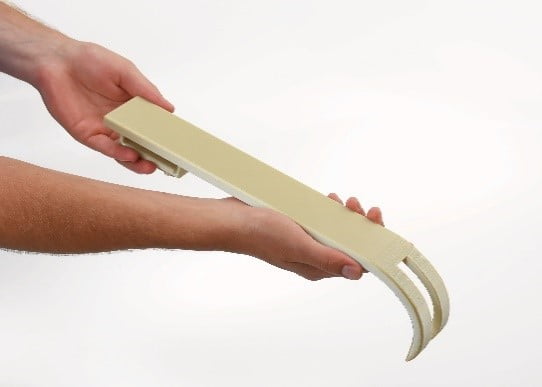

Stratasys’ ULTEM™ 9085 resin performance 3D-printing filaments meet aviation and railway fire, smoke and toxicity standards. The material is polyetherimide-based with non-halogenated flame retardants. Printed on Stratasys F900 FDM (fused deposition modelling) 3D printers, is tested for flame, smoke and toxicity to 14 CFR 25.853, BSS 7238 and 7239, and AITM 2.0007B & 3.0005 and EN45545-2 (e.g. all hazard levels HL1/2/3), demonstrating suitability for use in production for the railway rolling stock industry. Aviation parts including seating, panelling and ducting can be manufactured rapidly and economically, enabling aircraft cabin customisation, and are already certified by and used by Airbus. The material can also be used for 3D printed applications in automotive and other industries. Stratasys invented FDM 3D-printing 30 years ago and is today a world leader in industrial-scale 3D-printing machines and materials.

“Stratasys wins one of its largest ever aerospace orders”, 13 August 2020 https://www.aero-mag.com/stratasys-am-craft-3d-printing-13082020/