Boston Micro Fabrication and Henkel PIN FR PµSL printing resin micro-precision passes aerospace fire classifications. The PµSL (projection micro stereolithography) technology uses UV polymerisation of the Henkel liquid resin to achieve accurate 3D printing resolutions down to 2 µm. Henkel’s Loctite 3955 non-halogenated flame retardant resin enables 3D-print materials to achieve UL 94 V-0 (3 mm), glow wire ignition 850°C (1.5, 2 mm), ASTM E622 smoke generation and BSS 7239 smoke toxicity standards, and to pass demanding aerospace fire performance specifications (vertical burn and flame spread AirBus AITM2-0002, AITM2-0007, AITM3-0005). The black resin offers high modulus, flexural and tensile strength. The combination of precision microfabrication 3D printing and PIN FR fire, technical and ageing performance enables manufacture of miniaturised engineering and electronics components in sectors including transport and aviation, E&E and medical.

“How to Build Tiny Products by Using Microfabrication Techniques”, Design News, 3 July 2023 https://www.designnews.com/3dp/how-build-tiny-products-using-microfabrication-techniques

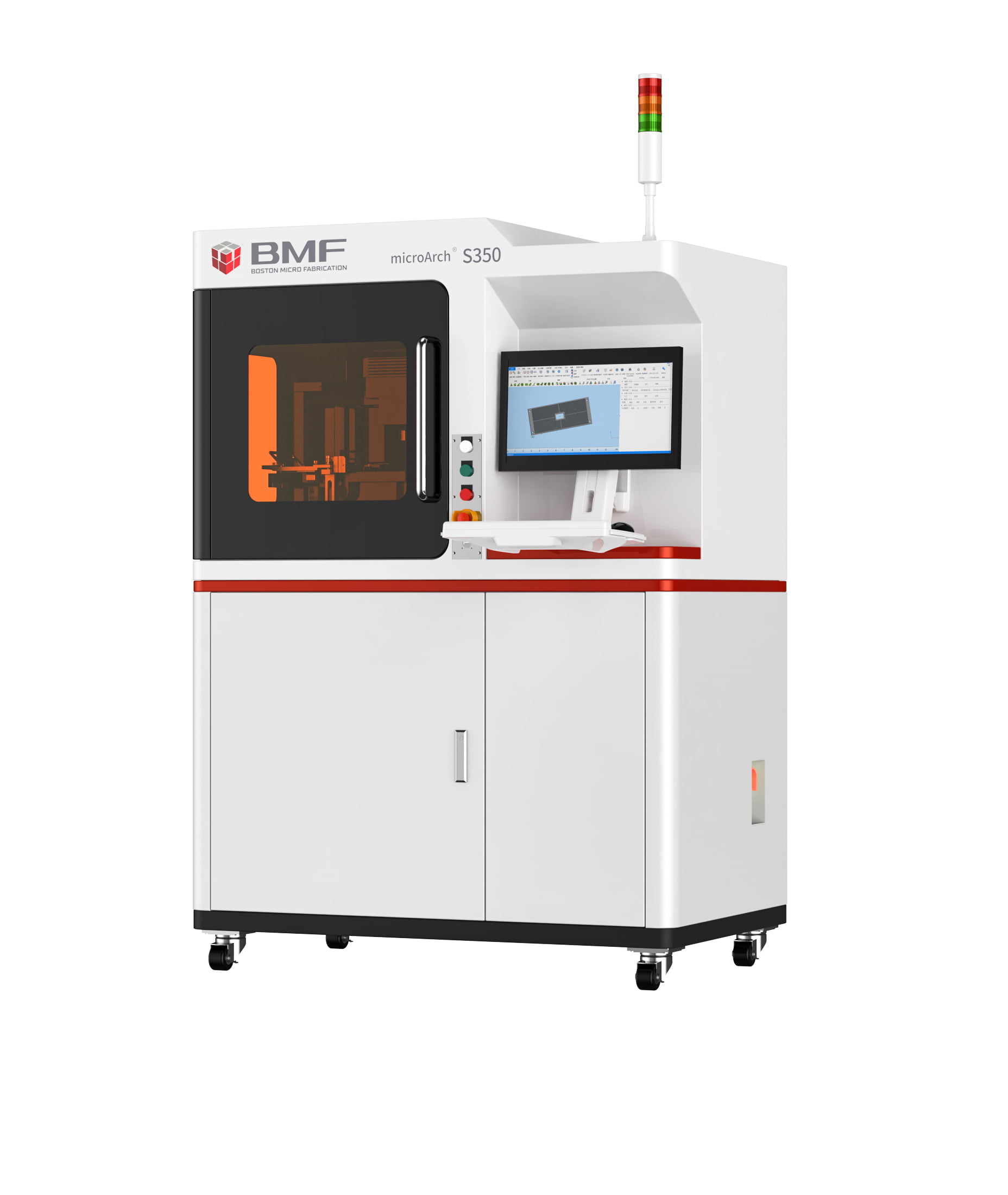

Boston Micro Fabrication https://bmf3d.com/

Henkel Loctite 3955 https://www.loctiteam.com/3955-flame-retardant/